WHY WATERJET

Take ordinary tap water and pressurize it to 60,000 psi (4,000 bar) and force it through a very small hole. Mix the water with garnet abrasive and you have a very thin stream of water traveling very fast that will rapidly erode most materials. Some waterjet projects require “water-only” and don’t add the garnet abrasive. These are used to cut softer materials, such as food, rubber, and foam.

Take ordinary tap water and pressurize it to 60,000 psi (4,000 bar) and force it through a very small hole. Mix the water with garnet abrasive and you have a very thin stream of water traveling very fast that will rapidly erode most materials. Some waterjet projects require “water-only” and don’t add the garnet abrasive. These are used to cut softer materials, such as food, rubber, and foam.

Waterjets can cut just about any materials that are placed in front of them. The waterjet can cut intricate shapes not possible using traditional methods which makes it a preferred cutting process.

Waterjet Advantage

Our state of the art waterjet cutting technology has significant competitive advantages over traditional cutting methods.

- Large 12′ x 20′ cutting envelope

- Four cutting heads

- Intricate, fine detail cuts

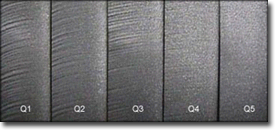

- High Quality finish

- Tolerances up to ±.003″

- Fast set-up and programming

- Tight parts nesting

- No heat-affected zone

- No ash or carbon deposits

- No part distortion

- No tooling costs

- Minimal Burr

- Very short lead times

- Efficient and Cost Effective